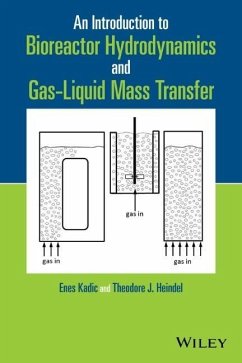

This book reviews and compares the major types of bioreactors used to produce renewable fuels, chemicals, medicines, and proteins, by providing an overview of the hydrodynamics and gas-liquid mass transfer operations in this equipment. These operations are important because they influence the quality and quantity of the desired material produced in the reactor. The text also discusses advantages and disadvantages of each bioreactor and provides a procedure for optimal bioreactor selection based on current process needs, giving chemical and mechanical engineers a practical, working reference.

Reviews and compares the major types of bioreactors, defines their pros and cons, and identifies research needs and figures of merit that have yet to be addressed

Describes common modes of operation in bioreactors

Covers the three common bioreactor types, including stirred-tank bioreactors, bubble column bioreactors, and airlift bioreactors

Details less common bioreactors types, including fixed bed bioreactors and novel bioreactor designs

Discusses advantages and disadvantages of each bioreactor and provides a procedure for optimal bioreactor selection based on current process needs

Reviews the problems of bioreactor selection globally while considering all bioreactor options rather than concentrating on one specific bioreactor type

Hinweis: Dieser Artikel kann nur an eine deutsche Lieferadresse ausgeliefert werden.

Reviews and compares the major types of bioreactors, defines their pros and cons, and identifies research needs and figures of merit that have yet to be addressed

Describes common modes of operation in bioreactors

Covers the three common bioreactor types, including stirred-tank bioreactors, bubble column bioreactors, and airlift bioreactors

Details less common bioreactors types, including fixed bed bioreactors and novel bioreactor designs

Discusses advantages and disadvantages of each bioreactor and provides a procedure for optimal bioreactor selection based on current process needs

Reviews the problems of bioreactor selection globally while considering all bioreactor options rather than concentrating on one specific bioreactor type

Hinweis: Dieser Artikel kann nur an eine deutsche Lieferadresse ausgeliefert werden.