Bioprocessing of Renewable Res

Versandkostenfrei!

Versandfertig in über 4 Wochen

146,99 €

inkl. MwSt.

Weitere Ausgaben:

PAYBACK Punkte

73 °P sammeln!

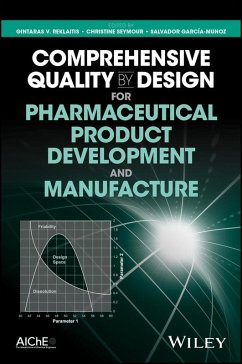

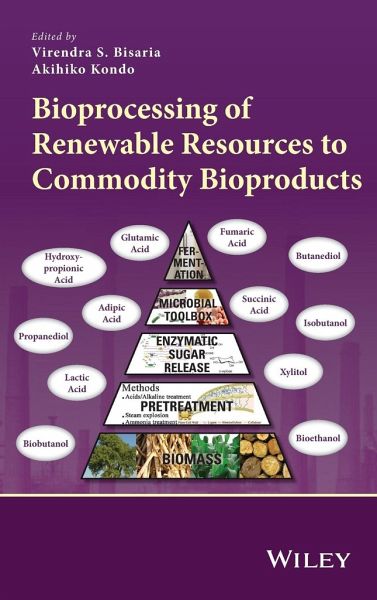

It is universally agreed that the era of cheap fossil oil is going to be over soon. Offering timely solutions to our current energy crisis, Bioprocessing of Renewable Resources to Commodity Bioproducts addresses the latest genetic and metabolic engineering approaches towards the development of recombinant microorganisms for the production of commodity byproducts. Suitable for researchers, practitioners, students, and consultants, the text provides a unique perspective to the industry about the scientific problems and their possible solutions in making a bioprocess work for commercial production of these commodity byproducts.

This book provides the vision of a successful biorefinery-the lignocelluloic biomass needs to be efficiently converted to its constituent monomers, comprising mainly of sugars such as glucose, xylose, mannose and arabinose. Accordingly, the first part of the book deals with aspects crucial for the pretreatment and hydrolysis of biomass to give sugars in high yield, as well as the general aspects of bioprocessing technologies which will enable the development of biorefineries through inputs of metabolic engineering, fermentation, downstream processing and formulation. The second part of the book gives the current status and future directions of the biological processes for production of ethanol (a biofuel as well as an important commodity raw material), solvents (butanol, isobutanol, butanediols, propanediols), organic acids (lactic acid, 3-hydroxy propionic acid, fumaric acid, succinic acid and adipic acid), and amino acid (glutamic acid). The commercial production of some of these commodity bioproducts in the near future will have a far reaching effect in realizing our goal of sustainable conversion of these renewable resources and realizing the concept of biorefinery.

Suitable for researchers, practitioners, graduate students and consultants in biochemical/ bioprocess engineering, industrial microbiology, bioprocess technology, metabolic engineering, environmental science and energy, the book offers:

- Exemplifies the application of metabolic engineering approaches for development of microbial cell factories

- Provides a unique perspective to the industry about the scientific problems and their possible solutions in making a bioprocess work for commercial production of commodity bioproducts

- Discusses the processing of renewable resources, such as plant biomass, for mass production of commodity chemicals and liquid fuels to meet our ever- increasing demands

- Encourages sustainable green technologies for the utilization of renewable resources

- Offers timely solutions to help address the energy problem as non-renewable fossil oil will soon be unavailable

Suitable for researchers, practitioners, graduate students and consultants in biochemical/ bioprocess engineering, industrial microbiology, bioprocess technology, metabolic engineering, environmental science and energy, the book offers:

- Exemplifies the application of metabolic engineering approaches for development of microbial cell factories

- Provides a unique perspective to the industry about the scientific problems and their possible solutions in making a bioprocess work for commercial production of commodity bioproducts

- Discusses the processing of renewable resources, such as plant biomass, for mass production of commodity chemicals and liquid fuels to meet our ever- increasing demands

- Encourages sustainable green technologies for the utilization of renewable resources

- Offers timely solutions to help address the energy problem as non-renewable fossil oil will soon be unavailable