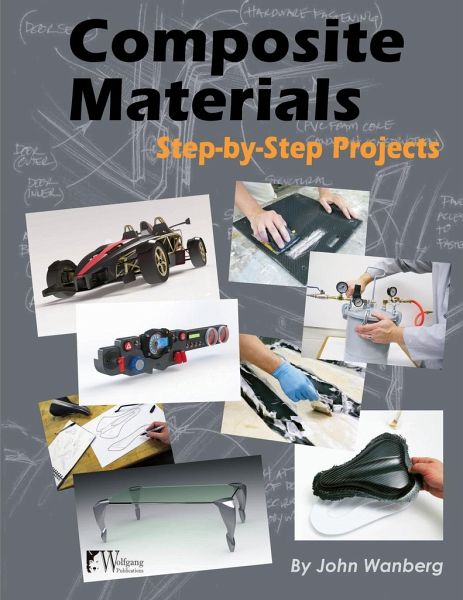

Composite Materials

Step-By-Step Projects

Versandkostenfrei!

Nicht lieferbar

Weitere Ausgaben:

In books one through three, author and Professor John Wanberg took pains to explain the why and how of building with Composite Materials. In this new book of Step-by-Step Projects, John takes a different approach. Instead of explaining the theory and what each component is made of, John cuts to the chase. Nearly every page is allocated to photos, photos and more photos. The pictures lead the reader through a series of detailed how-to sequences. From making the mold, to cutting the fabric, creating a vacuum bag, and finishing the part, all the information is here. Projects include everything fr...

In books one through three, author and Professor John Wanberg took pains to explain the why and how of building with Composite Materials. In this new book of Step-by-Step Projects, John takes a different approach. Instead of explaining the theory and what each component is made of, John cuts to the chase. Nearly every page is allocated to photos, photos and more photos. The pictures lead the reader through a series of detailed how-to sequences. From making the mold, to cutting the fabric, creating a vacuum bag, and finishing the part, all the information is here. Projects include everything from fabricating a bicycle seat to making the nose-piece for a race car. Some projects require only simple molds, while others require the use of a vacuum bag and pressure-enclosure. All are designed for fabricators working in their own small shop or garage. Each chapter starts with copy, just enough to explain the project and the goals. The vast majority of each chapter however, is given over to the how-to photos. Photos that show each step along the way - from the initial sketch to the finished part. If what you need is a good reason to manufacture your own very strong and very light parts, this book contains nine separate reasons.