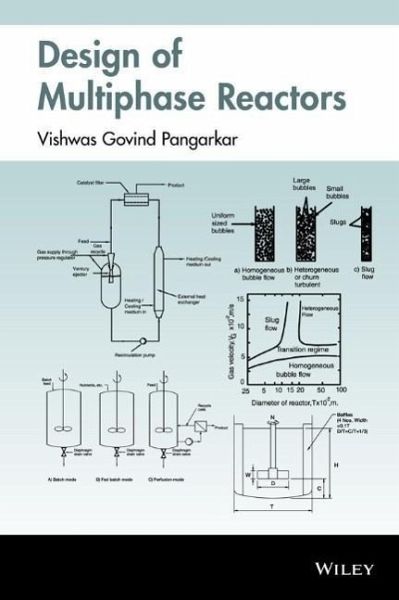

Design of Multiphase Reactors

Versandkostenfrei!

Versandfertig in über 4 Wochen

124,99 €

inkl. MwSt.

Weitere Ausgaben:

PAYBACK Punkte

62 °P sammeln!

Details simple design methods for multiphase reactors in the chemical process industries

Includes basic aspects of transport in multiphase reactors and the importance of relatively reliable and simple procedures for predicting mass transfer parameters

Details of design and scale up aspects of several important types of multiphase reactors

Examples illustrated through design methodologies presenting different reactors for reactions that are industrially important

Includes simple spreadsheet packages rather than complex algorithms / programs or computational aid

Includes basic aspects of transport in multiphase reactors and the importance of relatively reliable and simple procedures for predicting mass transfer parameters

Details of design and scale up aspects of several important types of multiphase reactors

Examples illustrated through design methodologies presenting different reactors for reactions that are industrially important

Includes simple spreadsheet packages rather than complex algorithms / programs or computational aid