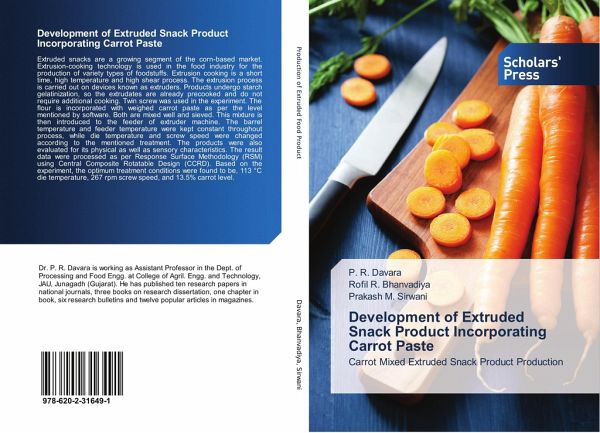

Development of Extruded Snack Product Incorporating Carrot Paste

Carrot Mixed Extruded Snack Product Production

Versandkostenfrei!

Versandfertig in 1-2 Wochen

52,99 €

inkl. MwSt.

PAYBACK Punkte

26 °P sammeln!

Extruded snacks are a growing segment of the corn-based market. Extrusion-cooking technology is used in the food industry for the production of variety types of foodstuffs. Extrusion cooking is a short time, high temperature and high shear process. The extrusion process is carried out on devices known as extruders. Products undergo starch gelatinization, so the extrudates are already precooked and do not require additional cooking. Twin screw was used in the experiment. The flour is incorporated with weighed carrot paste as per the level mentioned by software. Both are mixed well and sieved. T...

Extruded snacks are a growing segment of the corn-based market. Extrusion-cooking technology is used in the food industry for the production of variety types of foodstuffs. Extrusion cooking is a short time, high temperature and high shear process. The extrusion process is carried out on devices known as extruders. Products undergo starch gelatinization, so the extrudates are already precooked and do not require additional cooking. Twin screw was used in the experiment. The flour is incorporated with weighed carrot paste as per the level mentioned by software. Both are mixed well and sieved. This mixture is then introduced to the feeder of extruder machine. The barrel temperature and feeder temperature were kept constant throughout process, while die temperature and screw speed were changed according to the mentioned treatment. The products were also evaluated for its physical as well as sensory characteristics. The result data were processed as per Response Surface Methodology (RSM) using Central Composite Rotatable Design (CCRD). Based on the experiment, the optimum treatment conditions were found to be, 113 °C die temperature, 267 rpm screw speed, and 13.5% carrot level.