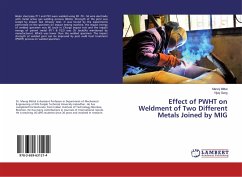

Boiler steel pipe P11 and P22 were welded using ER -70 - S6 wire electrode with metal active gas welding process (MAG). Strength of the joint was tested by impact test (Charpy test). It was found by the experiments performed on the specimen on impact testing machine, the impact energy of welded specimen was 46 Joule in Charpy impact test and the impact energy of parent metal (P11 & P22) was 35 Joule(As mentioned by manufacturer). Which was lower than the welded specimen. The impact strength of welded joint can be improved by post weld heat treatment (PWHT) process on welded specimen.

Bitte wählen Sie Ihr Anliegen aus.

Rechnungen

Retourenschein anfordern

Bestellstatus

Storno