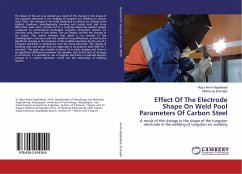

Effect Of The Electrode Shape On Weld Pool Parameters Of Carbon Steel

A result of the change in the shape of the tungsten electrode in the welding of tungsten arc welding

Versandkostenfrei!

Versandfertig in 6-10 Tagen

37,99 €

inkl. MwSt.

PAYBACK Punkte

19 °P sammeln!

The shape of the arc was studied as a result of the change in the shape of the tungsten electrode in the welding of tungsten arc welding on carbon steel. Then, the changes in the weld metal due to electric arc change were studied. Hardness, metallography, bending and tensile tests and X-ray diffraction tests were carried out in a tungsten-electrode-welded sample compared to conventional tip-shaped tungsten electrodes. Electric arc shooting took place in two states. The arc images confirm the change in arc shape. The results showed that there is no change in the metallographic structures and th...

The shape of the arc was studied as a result of the change in the shape of the tungsten electrode in the welding of tungsten arc welding on carbon steel. Then, the changes in the weld metal due to electric arc change were studied. Hardness, metallography, bending and tensile tests and X-ray diffraction tests were carried out in a tungsten-electrode-welded sample compared to conventional tip-shaped tungsten electrodes. Electric arc shooting took place in two states. The arc images confirm the change in arc shape. The results showed that there is no change in the metallographic structures and the results of X-ray diffraction, as well as the significant change in the hardness of the welded specimens by the use of a tungsten electrode in comparison with the sharp electrode. The results of bending tests and tensile tests are approved in accordance with AWS D1.1 standard. The grain size number is about 10 in both samples and there is no significant difference between the samples. Due to the lack of changes in structures, it is possible to use a tungsten electrode in required sections instead of a notche electrode, which has the advantage of welding specific.