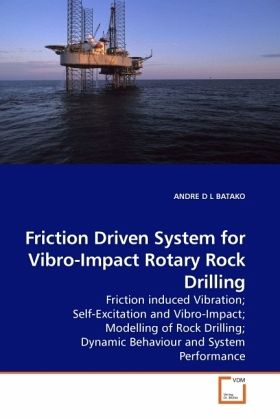

Friction Driven System for Vibro-Impact Rotary Rock Drilling

Friction induced Vibration; Self-Excitation and Vibro-Impact; Modelling of Rock Drilling; Dynamic Behaviour and System Performance

Versandkostenfrei!

Versandfertig in 6-10 Tagen

52,99 €

inkl. MwSt.

PAYBACK Punkte

26 °P sammeln!

In recent years, a high level of awareness of environmental issues led to soaring oil prices. These events evoked the introduction of national, international regulations and policies of how industries deal with pollution and energy consumption. In oil drilling practice, it has been reported that large amounts of the energy imparted to the drill-string is consumed by friction in the system. This book makes an attempt, if not to recover, then at least utilise the energy consumed by friction. The book presents a new principle of vibro-impact rotary drilling system that recovers the energy consume...

In recent years, a high level of awareness of environmental issues led to soaring oil prices. These events evoked the introduction of national, international regulations and policies of how industries deal with pollution and energy consumption. In oil drilling practice, it has been reported that large amounts of the energy imparted to the drill-string is consumed by friction in the system. This book makes an attempt, if not to recover, then at least utilise the energy consumed by friction. The book presents a new principle of vibro-impact rotary drilling system that recovers the energy consumed by the friction by storing it in a spring. The mechanism then uses this energy to produce impacts. This work shows a new approach to harness friction and various phenomena are studied. A pilot study provides supporting materials. Engineers and mathematicians will find their interest in this work in terms of engineering applications, system dynamics and mathematical issues leading to bifurcation and chaos when the model performs multiple impacts. This analysis shows how to exploit friction work and helps specialists or anyone exploring friction and self-excited vibro-impact systems.