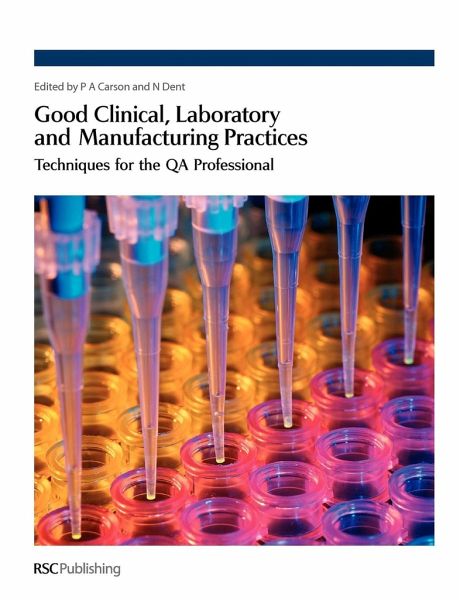

Good Clinical, Laboratory and Manufacturing Practices

Techniques for the Qa Professional

Herausgeber: Carson, Philip; Dent, Nigel

Versandkostenfrei!

Versandfertig in über 4 Wochen

250,99 €

inkl. MwSt.

PAYBACK Punkte

125 °P sammeln!

Written by a team of world experts, the book provides practical and detailed advice for the quality assurance professional responsible for monitoring compliance with legal requirements and accepted standards of pre-clinical safety studies, clinical trials and manufacture of drugs. It provides a framework for integrating these standards with other quality management systems. Detailed examples are provided to illustrate application of the principles. The book is targeted primarily at all those subjected to internal and external inspection and audit for compliance with the requirements of good cl...

Written by a team of world experts, the book provides practical and detailed advice for the quality assurance professional responsible for monitoring compliance with legal requirements and accepted standards of pre-clinical safety studies, clinical trials and manufacture of drugs. It provides a framework for integrating these standards with other quality management systems. Detailed examples are provided to illustrate application of the principles. The book is targeted primarily at all those subjected to internal and external inspection and audit for compliance with the requirements of good clinical, good laboratory, and good manufacturing practices. It will be of value to chemists, clinicians, ecotoxicologists, operation managers, pharmaceutical process managers, quality assurance officers, technicians, and toxicologists.