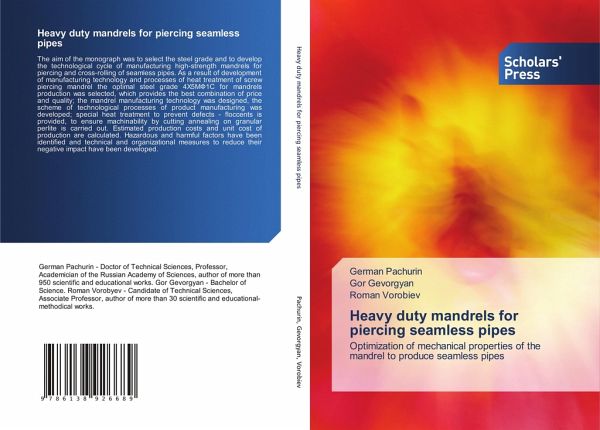

Heavy duty mandrels for piercing seamless pipes

Optimization of mechanical properties of the mandrel to produce seamless pipes

Versandkostenfrei!

Versandfertig in 6-10 Tagen

53,99 €

inkl. MwSt.

PAYBACK Punkte

27 °P sammeln!

The aim of the monograph was to select the steel grade and to develop the technological cycle of manufacturing high-strength mandrels for piercing and cross-rolling of seamless pipes. As a result of development of manufacturing technology and processes of heat treatment of screw piercing mandrel the optimal steel grade 4 5 1 for mandrels production was selected, which provides the best combination of price and quality; the mandrel manufacturing technology was designed, the scheme of technological processes of product manufacturing was developed; special heat treatment to prevent defects - floc...

The aim of the monograph was to select the steel grade and to develop the technological cycle of manufacturing high-strength mandrels for piercing and cross-rolling of seamless pipes. As a result of development of manufacturing technology and processes of heat treatment of screw piercing mandrel the optimal steel grade 4 5 1 for mandrels production was selected, which provides the best combination of price and quality; the mandrel manufacturing technology was designed, the scheme of technological processes of product manufacturing was developed; special heat treatment to prevent defects - floccents is provided, to ensure machinability by cutting annealing on granular perlite is carried out. Estimated production costs and unit cost of production are calculated. Hazardous and harmful factors have been identified and technical and organizational measures to reduce their negative impact have been developed.