High Temperature Processing of Milk and Milk Products

Versandkostenfrei!

Versandfertig in über 4 Wochen

192,99 €

inkl. MwSt.

Weitere Ausgaben:

PAYBACK Punkte

96 °P sammeln!

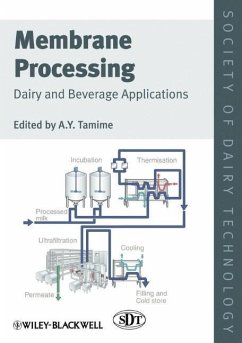

This book covers many aspects of thermal processing of milk and milk products with particular focus on UHT processing. It commences with an overview of the major thermal processing technologies: thermisation, pasteurisation, extended-shelf-life (ESL), UHT and in-container sterilisation. It discusses the principles of the technologies, the processing and packaging equipment used, processing issues such as temperature-time profiles, heat stability, fouling and cleaning, and the quality and safety aspects of the products produced. It provides a balance of the engineering aspects of the processes ...

This book covers many aspects of thermal processing of milk and milk products with particular focus on UHT processing. It commences with an overview of the major thermal processing technologies: thermisation, pasteurisation, extended-shelf-life (ESL), UHT and in-container sterilisation. It discusses the principles of the technologies, the processing and packaging equipment used, processing issues such as temperature-time profiles, heat stability, fouling and cleaning, and the quality and safety aspects of the products produced. It provides a balance of the engineering aspects of the processes and the chemical, microbiological and sensory aspects of the products. The changes that occur in products during processing and storage, and the related defects which can arise, are central to the book. The discussions of these changes will be an aid to industry personnel in identifying the causes of quality defects in these products and devising measures which can be taken to eliminate or minimise the defects.