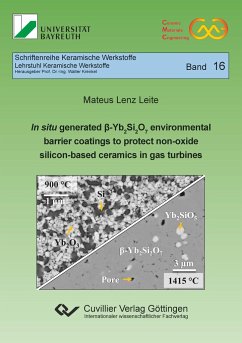

In face of an accelerating climate change, the reduction and substitution of fossil fuels is crucial to decarbonize energy production. Gas turbines can operate with versatile fuel sources like natural gas and future fuels such as hydrogen and ammonia. In a next future, thermal efficiencies above 65% are expected to be achieved by implementing non-oxide silicon-based (i.e. Si¿N¿, SiC and SiC/SiC) ceramic components. However, water vapor is one of the main combustion products, which leads to rapid corrosion due to the volatilization of the protective SiO¿ layer above 1200 °C. Hence, an in situ generated Yb¿Si¿O¿ double layered environmental barrier coating system composed of silazanes and the active fillers Yb2O3 and Si was processed at 1415 °C for 5 h in air to protect Si3N4, SiC and SiC/SiC from corrosion. The easy to apply coating system exhibits a dense microstructure with a thickness of up to 150 µm, besides an excellent adhesion strength (36.9 ± 6.2 MPa), hardness (6.9 ± 1.6 GPa) and scratch resistance (28 N). It remarkably overcomes over 15 thermal cycles between 1200 and 20 °C and shows almost no mass loss after harsh hot gas corrosion at 1200 °C for 200 h (pH2O = 0.15 atm, v = 100 m s¿¹).

Hinweis: Dieser Artikel kann nur an eine deutsche Lieferadresse ausgeliefert werden.

Hinweis: Dieser Artikel kann nur an eine deutsche Lieferadresse ausgeliefert werden.