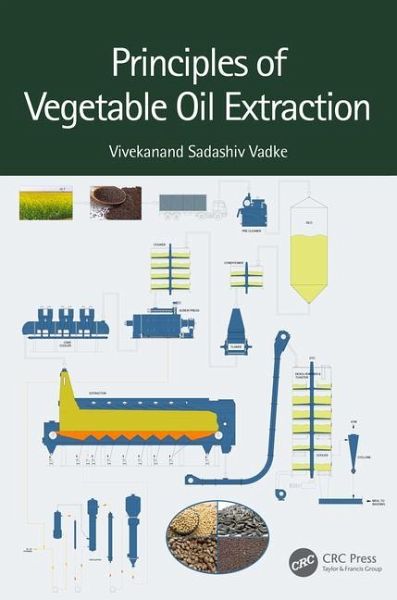

Principles of Vegetable Oil Extraction

Versandkostenfrei!

Versandfertig in 1-2 Wochen

169,99 €

inkl. MwSt.

Weitere Ausgaben:

PAYBACK Punkte

85 °P sammeln!

This book covers technology of vegetable oil extraction including theory, process technologies used for various oilseeds, machinery and operation and design aspects. Pertinent topics are covered under two parts as mechanical expression, and solvent extraction including modern press designs, effect of each unit operation and so forth.