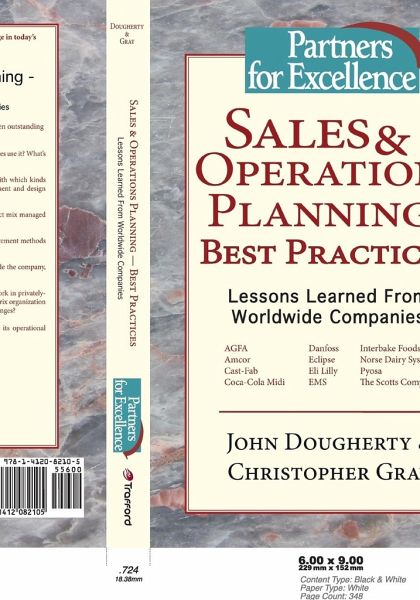

Sales & Operations Planning - Best Practices

Lessons Learned from Worldwide Companies

Versandkostenfrei!

Versandfertig in 1-2 Wochen

43,99 €

inkl. MwSt.

PAYBACK Punkte

22 °P sammeln!

Within this book, you'll be able to "go inside" a baker's dozen companies and learn how they use Sales & Operations Planning to run their businesses better. You'll meet large companies and smaller ones, household names and names not widely known, companies whose products you use and companies whose products you've never heard of. You'll also hear from the consultant who helped them implement S&OP. The Best Practices Companies are: Agfa Amcor Cast-Fab Coca-Cola Midi Danfoss Eclipse Eli Lilly EMS Interbake Foods Norse Dairy Products Pyosa The Scotts Company Unicorn Medical Learn: What is this th...

Within this book, you'll be able to "go inside" a baker's dozen companies and learn how they use Sales & Operations Planning to run their businesses better. You'll meet large companies and smaller ones, household names and names not widely known, companies whose products you use and companies whose products you've never heard of. You'll also hear from the consultant who helped them implement S&OP. The Best Practices Companies are: Agfa Amcor Cast-Fab Coca-Cola Midi Danfoss Eclipse Eli Lilly EMS Interbake Foods Norse Dairy Products Pyosa The Scotts Company Unicorn Medical Learn: What is this thing called S&OP and why do successful companies use it? What's involved, what are the steps, and how does it work? Where does S&OP work? With which kinds of products? With which kinds of customers? Does it help with the New Product Development and Design process? How are the demand and supply plans for the detailed product mix managed in a way that is consistent with the volume plans from S&OP? Is S&OP really needed in a company using Continuous Improvement methods like Lean Manufacturing or TQM/6 Sigma? How does S&OP work with Supply Chain Management: outside the company, with customers, and with suppliers? In what size company does S&OP work best? How does it work in privately-held companies, global companies and companies using a matrix organization structure? Does S&OP survive ownership or organization changes? How can a company be sure that its financial plans match its operational plans?