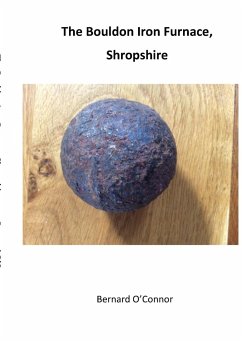

At the beginning of the English Civil War, the Royalist Army in Shropshire needed cannons and cannonballs. King Charles I's master of ordnance would have liaised with Sir Charles Smyth, the owner of land in Bouldon, a small hamlet about 10 km north-northeast of Ludlow Castle, for a charcoal iron furnace to be constructed on the bank above Pye brook. Ironstone was already being worked on the upper slopes of the Brown Clee and supplied to furnaces on the River Stour near Bridgnorth. Woodland on the lower slopes of the Clee Hills was being coppiced for the charcoal used to heat the iron. Local limestone quarries supplied the flux which helped separate the iron from the waste rock. Water was available from the brooks that drained the Clee Hills. A charcoal iron furnace was constructed in Bouldon which manufactured cannons and cannonballs for Ludlow and Bridgnorth castles. Later it produced pig iron which was reputed to be the best in Britain. Although the furnace changed hands several times, it provided wealth for its owners for over 150 years and stimulated the local economy by employing local men not just in the furnace but also in the casting shed, in the bell pit mines on the Clee Hills, the owners of packhorses and donkeys used to carry the ironstone and cordwood to the furnace site, the 'charkers' who made the charcoal, cartwrights, wheelwrights, carpenters, carters, horse owners, blacksmiths, forgers, accountants and others. Bernard O'Connor provides a detailed and illustrated account of an important part of Corvedale's industrial history.

Hinweis: Dieser Artikel kann nur an eine deutsche Lieferadresse ausgeliefert werden.

Hinweis: Dieser Artikel kann nur an eine deutsche Lieferadresse ausgeliefert werden.