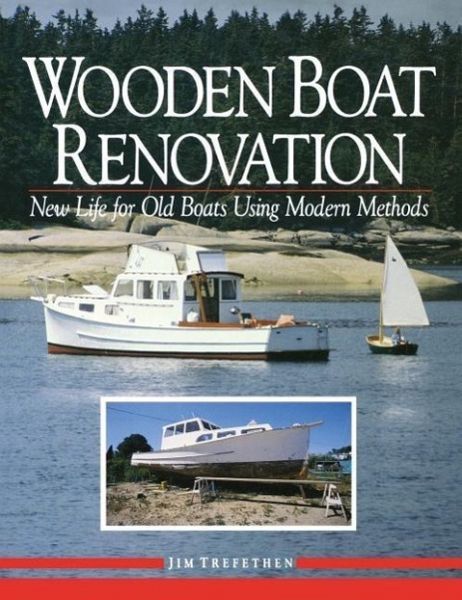

Wooden Boat Renovation: New Life for Old Boats Using Modern Methods

Versandkostenfrei!

Versandfertig in 2-4 Wochen

51,99 €

inkl. MwSt.

PAYBACK Punkte

26 °P sammeln!

Tells the reader how to select the right boat; establish a work schedule and budget; buy the right tools and equipment; select alternatives to endangered tropical rainforest woods; repair and modify the hull, topsides, deckhouse, masts, and interior. This title also tells when, why, and how to use fiberglass; paint and refinishing.