Applied Thermodynamics in Unit Operations (eBook, PDF)

Solved Examples on Energy, Exergy, and Economic Analyses of Processes

Versandkostenfrei!

Sofort per Download lieferbar

49,95 €

inkl. MwSt.

Weitere Ausgaben:

PAYBACK Punkte

25 °P sammeln!

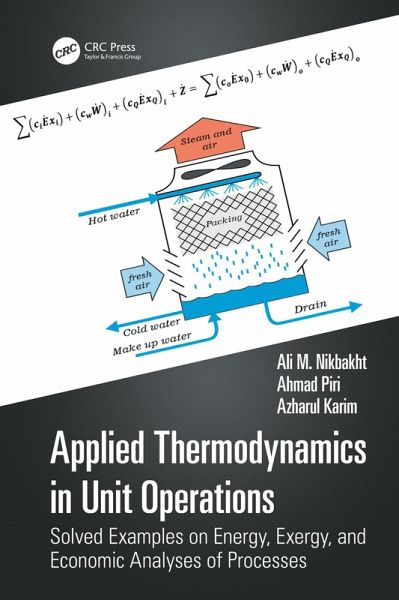

The growing demand of energy accounting in industries is the main challenge for academics and engineers working in chemical processing plants, food industries, and the energy sector. Applied Thermodynamics in Unit Operations addresses this demand and offers a clear contribution to the quantification of energy consumption in processes, while also solving the economic aspects of energy that are vital in real-life industrial contexts.Features: Combines the energy and exergy routines to analyze utilities and unit operations in a wide range of engineering scopes: nozzles, turbines, compressors, eva...

The growing demand of energy accounting in industries is the main challenge for academics and engineers working in chemical processing plants, food industries, and the energy sector. Applied Thermodynamics in Unit Operations addresses this demand and offers a clear contribution to the quantification of energy consumption in processes, while also solving the economic aspects of energy that are vital in real-life industrial contexts.

Features:

The book is a handy reference for researchers and practitioners in the areas of process, chemical, and mechanical engineering, undergraduate and postgraduate students in those disciplines, and engineers working in industry and production managers. Some examples are solved in EES to help the audience apply computer coding for thermal calculations.

Features:

- Combines the energy and exergy routines to analyze utilities and unit operations in a wide range of engineering scopes: nozzles, turbines, compressors, evaporators, HVAC, drying technology, steam handling, and power generation

- Offers a detailed procedure of finding economic wealth of energy in the operations

- Discusses basic concepts of thermal engineering and industrial operational insights through practiced examples, schematic illustrations, and software codes

- The only book to include practical problems of industrial operations solved in detail and complementary EES codes for the solutions

- Features examples selected from authors' real-world experience in industrial projects

The book is a handy reference for researchers and practitioners in the areas of process, chemical, and mechanical engineering, undergraduate and postgraduate students in those disciplines, and engineers working in industry and production managers. Some examples are solved in EES to help the audience apply computer coding for thermal calculations.

Dieser Download kann aus rechtlichen Gründen nur mit Rechnungsadresse in A, B, BG, CY, CZ, D, DK, EW, E, FIN, F, GR, HR, H, IRL, I, LT, L, LR, M, NL, PL, P, R, S, SLO, SK ausgeliefert werden.