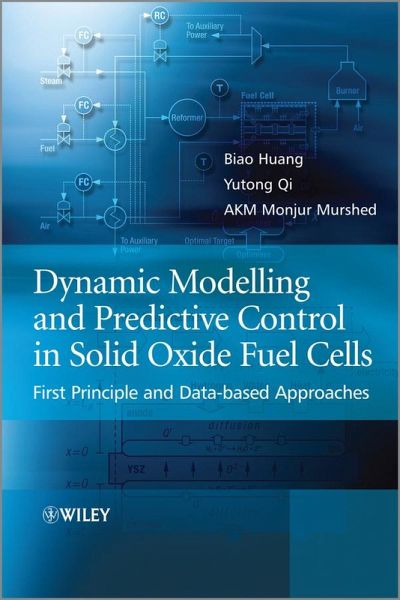

Dynamic Modeling and Predictive Control in Solid Oxide Fuel Cells (eBook, PDF)

First Principle and Data-based Approaches

PAYBACK Punkte

0 °P sammeln!

The high temperature solid oxide fuel cell (SOFC) is identified as one of the leading fuel cell technology contenders to capture the energy market in years to come. However, in order to operate as an efficient energy generating system, the SOFC requires an appropriate control system which in turn requires a detailed modelling of process dynamics. Introducting state-of-the-art dynamic modelling, estimation, and control of SOFC systems, this book presents original modelling methods and brand new results as developed by the authors. With comprehensive coverage and bringing together many aspects o...

The high temperature solid oxide fuel cell (SOFC) is identified as one of the leading fuel cell technology contenders to capture the energy market in years to come. However, in order to operate as an efficient energy generating system, the SOFC requires an appropriate control system which in turn requires a detailed modelling of process dynamics. Introducting state-of-the-art dynamic modelling, estimation, and control of SOFC systems, this book presents original modelling methods and brand new results as developed by the authors. With comprehensive coverage and bringing together many aspects of SOFC technology, it considers dynamic modelling through first-principles and data-based approaches, and considers all aspects of control, including modelling, system identification, state estimation, conventional and advanced control. Key features: * Discusses both planar and tubular SOFC, and detailed and simplified dynamic modelling for SOFC * Systematically describes single model and distributed models from cell level to system level * Provides parameters for all models developed for easy reference and reproducing of the results * All theories are illustrated through vivid fuel cell application examples, such as state-of-the-art unscented Kalman filter, model predictive control, and system identification techniques to SOFC systems The tutorial approach makes it perfect for learning the fundamentals of chemical engineering, system identification, state estimation and process control. It is suitable for graduate students in chemical, mechanical, power, and electrical engineering, especially those in process control, process systems engineering, control systems, or fuel cells. It will also aid researchers who need a reminder of the basics as well as an overview of current techniques in the dynamic modelling and control of SOFC.

Dieser Download kann aus rechtlichen Gründen nur mit Rechnungsadresse in D ausgeliefert werden.