Live-Line Operation and Maintenance of Power Distribution Networks (eBook, ePUB)

Versandkostenfrei!

Sofort per Download lieferbar

120,99 €

inkl. MwSt.

Weitere Ausgaben:

PAYBACK Punkte

0 °P sammeln!

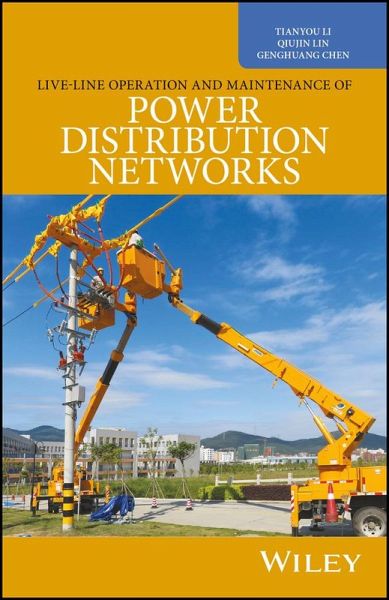

Excellent reference outlining the technical basis and working principles of live-line working, with current application technology, tools and working methods Introduces live-line working technology for the operation and maintenance of medium and low voltage power distribution networks, covering both the methods and techniques of live-line working on distribution networks with O&M field practices and experiences Elaborates the technical basis and working principles of live-line working in detail, with current application technology, tools and working methods Combining theory and practice close...

Excellent reference outlining the technical basis and working principles of live-line working, with current application technology, tools and working methods

- Introduces live-line working technology for the operation and maintenance of medium and low voltage power distribution networks, covering both the methods and techniques of live-line working on distribution networks with O&M field practices and experiences

- Elaborates the technical basis and working principles of live-line working in detail, with current application technology, tools and working methods

- Combining theory and practice closely, it provides technical guidance and helpful references to technical personnel who are engaged in distribution operation management, as well as related academics and researchers

- Written by a team of authors with extensive experience in both industry and academic fields, providing first-hand testimony of the issues facing electricity distribution companies, and offering sound theoretical foundations and rich field experiences

Dieser Download kann aus rechtlichen Gründen nur mit Rechnungsadresse in D ausgeliefert werden.