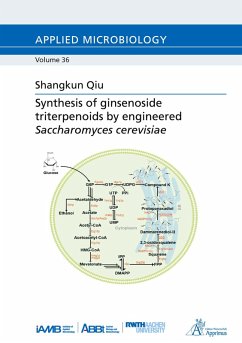

Ginseng is a traditional plant in Chinese medicine because it includes pharmaceutical ginsenosides that have been used in Asia for thousands of years. Ginsenosides are triterpenoids, a class of natural products mainly present in Panax species (e.g., Panax ginseng, P. notoginseng, and P. quinquifolium). However, due to the shortcomings of chemical synthesis and extraction from plants, the synthesis of ginsenosides by microbial cell factories, which has the advantages of environmental friendliness, high efficiency, convenience, and potentially low cost, has received much attention in recent years. In the present thesis, we designed the DoE experiment by Design Expert 11 (Stat-Ease, Inc.) and analyzed the final result by ordinary least squares (OLS) estimation. It showed that glucose, glutamate, salts, temperature, and oxygen play a crucial role in influencing final protopanaxadiol production. The five parameters were investigated during fermentation to improve the final protopanaxadiol production. Finally, we have got an optimized M3 medium, which vastly increases the final protopanaxadiol production to 1.2 g/L in shake flasks with a membrane lid at 28 , 8-fold compared to the original fermentation condition. This M3 medium also works for other engineered strains that vastly produce other triterpenoids (e.g., betulin, betulinic acid, and ginsenoside Compound K). Extracellular production of triterpenoids would be a key strategy to increase the final target triterpenoids production and promote the downstream purification processes. Given this, we added different hydrophobic compounds during the fermentation to carry out in-situ extraction. Different vegetable oils, isopropyl myristate, and dodecane were tested. Finally, almost all the dammarenediol-II and protopanaxadiol produced by the engineered yeast were secreted when vegetable oil was added during the fermentation. In addition, the yeast cells can be repeatedly used for subsequent fermentation rounds after adding isopropyl myristate or vegetable oils to extract all the dammarenediol-II and protopanaxadiol. In summary, as the cultivation conditions are easily established and transferable to Compound K and betulin producers, the study might facilitate the evaluation of engineered strains in microtiter plates and shake flask cultivations. The amounts of triterpenoid produced enable advanced analytics and even facilitate first ideas for purification of this intriguing class of natural products.