- Broschiertes Buch

- Merkliste

- Auf die Merkliste

- Bewerten Bewerten

- Teilen

- Produkt teilen

- Produkterinnerung

- Produkterinnerung

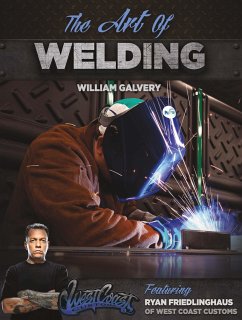

This unique and original book improves upon the shortcomings of competitive titles by providing complete, in-depth coverage of the equipment and techniques used in the most popular welding processes: oxyacetylene, stick welding, MIG welding, and TIG welding. Although the bulk of the book is devoted to the more popular welding techniques, the authors also provide a chapter on soldering and brazing and another on plasma cutting. The Art of Welding is perfect for anyone who wants to learn welding to make repairs or as part of a hobby, including experienced welders who will find a number of tips…mehr

Andere Kunden interessierten sich auch für

![Lean Maintenance Lean Maintenance]() Joel LevittLean Maintenance79,99 €

Joel LevittLean Maintenance79,99 €![Proceedings of the 35th International Matador Conference Proceedings of the 35th International Matador Conference]() Proceedings of the 35th International Matador Conference155,99 €

Proceedings of the 35th International Matador Conference155,99 €![Proceedings of the 34th International Matador Conference Proceedings of the 34th International Matador Conference]() Srichand Hinduja (ed.)Proceedings of the 34th International Matador Conference109,99 €

Srichand Hinduja (ed.)Proceedings of the 34th International Matador Conference109,99 €![Machine Shop Practice: Volumes 1 & 2 Machine Shop Practice: Volumes 1 & 2]() Karl MoltrechtMachine Shop Practice: Volumes 1 & 2100,99 €

Karl MoltrechtMachine Shop Practice: Volumes 1 & 2100,99 €![Machine Shop Practice: Volume 1 Machine Shop Practice: Volume 1]() Karl Hans MoltrechtMachine Shop Practice: Volume 168,99 €

Karl Hans MoltrechtMachine Shop Practice: Volume 168,99 €![Advanced Welding Techniques Advanced Welding Techniques]() Advanced Welding Techniques177,99 €

Advanced Welding Techniques177,99 €![Value Driven Product Planning and Systems Engineering Value Driven Product Planning and Systems Engineering]() Harry E. CookValue Driven Product Planning and Systems Engineering93,99 €

Harry E. CookValue Driven Product Planning and Systems Engineering93,99 €-

-

-

This unique and original book improves upon the shortcomings of competitive titles by providing complete, in-depth coverage of the equipment and techniques used in the most popular welding processes: oxyacetylene, stick welding, MIG welding, and TIG welding. Although the bulk of the book is devoted to the more popular welding techniques, the authors also provide a chapter on soldering and brazing and another on plasma cutting. The Art of Welding is perfect for anyone who wants to learn welding to make repairs or as part of a hobby, including experienced welders who will find a number of tips and procedures to improve their welding technique. FEATURES In-depth coverage of the equipment and techniques used in the most popular welding processes, including oxyacetylene, stick welding, MIG welding, and TIG welding. Features the pros and cons of each process and information on equipment, setup, materials, safety in each chapter. Presents information in a lively, easy-to-follow design. Provides a solid footing for the novice welder through a chapter that presents an overview of welding and another on tools and materials.

Hinweis: Dieser Artikel kann nur an eine deutsche Lieferadresse ausgeliefert werden.

Hinweis: Dieser Artikel kann nur an eine deutsche Lieferadresse ausgeliefert werden.

Produktdetails

- Produktdetails

- Verlag: Industrial Press

- Seitenzahl: 272

- Erscheinungstermin: 21. Oktober 2013

- Englisch

- Abmessung: 279mm x 222mm x 20mm

- Gewicht: 888g

- ISBN-13: 9780831134754

- ISBN-10: 0831134755

- Artikelnr.: 38079257

- Herstellerkennzeichnung

- Libri GmbH

- Europaallee 1

- 36244 Bad Hersfeld

- gpsr@libri.de

- Verlag: Industrial Press

- Seitenzahl: 272

- Erscheinungstermin: 21. Oktober 2013

- Englisch

- Abmessung: 279mm x 222mm x 20mm

- Gewicht: 888g

- ISBN-13: 9780831134754

- ISBN-10: 0831134755

- Artikelnr.: 38079257

- Herstellerkennzeichnung

- Libri GmbH

- Europaallee 1

- 36244 Bad Hersfeld

- gpsr@libri.de

William Galvery graduated from California State University, Long Beach with a Bachelor of Vocational Education. Professor Galvery has more than 30 years of industrial welding experience. He is an American Welding Society (AWS) Certified Welding Inspector and a Certified Welding Educator. In 2003 the AWS presented him with the Howard E. Adkins Memorial Instructor Award, its prestigious national teaching recognition award. And for the second time he was chosen AWS District 21 Educator of the Year. Also in 2003, Bill was also presented with an Excellence in Education Award by the University of Texas, Austin. Bill has served as an officer for the AWS Long Beach/Orange County Section and recently retired as Professor of Welding Technology and Welding Department coordinator at Orange Coast College in Costa Mesa, California.

Chapter 1: An Overview of Welding

* What are the most popular welding processes for the

do-it-yourselfer?

* How are welding joints prepared?

* What are some of the basic types of welds?

* What are the special procedures for welding thick plates?

* What are some common welding positions?

Chapter 2: General Tools, Materials and Safety Equipment

* What hand tools are used in welding?

* What power tools are used in welding?

* What types of clamps are used in welding?

* What are the most common steel products used in welding?

* What are some basic safety requirements?

Chapter 3: Oxyacetylene Welding

* What are the applications that OAW is best suited for?

* What metals can the OAW process readily weld?

* What are some basic safety procedures?

* What types of equipment are needed?

* How do you select filler metal (welding rod)?

* How is the equipment set up?

* What are the joint preparations for welding?

* How are welds judged?

* Oxyacetylene welding tips from West Coast Customs

Chapter 4: Shielded Metal Arc Welding: Arc Welding and Stick Welding

* How does the process work?

* When can stick welding be used?

* What is the basic equipment setup for stick welding?

* What are the functions of stick welding electrodes and how are they

selected?

* How is stick welding equipment set up?

* Stick welding tips from West Coast Customs

Chapter 5: Wire Feed Welding Processes: MIG Welding and Fluxed Cored Arc

Welding

* How does the MIG process work?

* What metals can MIG weld?

* What is the basic equipment for MIG Welding?

* How do you select MIG electrodes?

* What part does shielding gas play in the MIG process?

* How is the welding wire transferred to the welding pool?

* How is MIG equipment set up?

* What are some joint preparation steps for MIG welding?

* How does the orientation of the electrode during welding affect the

weld?

* What are typical MIG welding problems and solutions?

* How does the flux cored arc welding process work?

* What equipment is needed for an FCAW welding outfit?

* How do you select FCAW electrodes?

* What are typical FCAW problems and solutions?

* How is FCAW equipment set up?

* MIG welding tips from West Coast Customs

Chapter 6: Gas Tungsten Arc Welding: TIG Welding

* How does the process work?

* What is the basic equipment setup for TIG welding?

* How are the electrodes selected?

* What shielding gases are used with TIG welding?

* What is the TIG welding setup process?

* What are some problems and solutions for TIG welding?

* TIG welding tips from West Coast Customs

Chapter 7: Thermal Cutting: Oxy-Fuel Cutting and Plasma Arc Cutting

* How does oxyacetylene cutting work?

* How does a cutting head differ from a welding torch?

* What other fuels can be used in oxy-fuel cutting?

* How do you set up cutting torch equipment?

* What are some basic cutting techniques?

* What are OFC troubleshooting techniques?

* What is plasma arc cutting?

* Plasma arc cutting tips from West Coast Customs

Chapter 8: Brazing and Soldering

* What’s the difference between brazing and soldering?

* What are the types of brazing/soldering?

* What are some common joint designs?

* What’s the purpose of brazing and soldering fluxes?

* What are the properties of brazing filler materials and soldering

alloys?

* What steps help ensure safe brazing and soldering?

* How do you solder copper tubing?

* What are some troubleshooting tips for soldered and brazed joints?

* Braze Welding tips from West Coast Customs

Chapter 9: Welding Tasks and Tips

* What’s the best corner treatment for a welded rectangular frame?

* What’s the best way to check if corners are square?

* How should a cracked C-channel truck frame be repaired?

* What are some tips for welding pipe and tubing?

* What are some ways to deal with metal distortion?

Glossary

Index

* What are the most popular welding processes for the

do-it-yourselfer?

* How are welding joints prepared?

* What are some of the basic types of welds?

* What are the special procedures for welding thick plates?

* What are some common welding positions?

Chapter 2: General Tools, Materials and Safety Equipment

* What hand tools are used in welding?

* What power tools are used in welding?

* What types of clamps are used in welding?

* What are the most common steel products used in welding?

* What are some basic safety requirements?

Chapter 3: Oxyacetylene Welding

* What are the applications that OAW is best suited for?

* What metals can the OAW process readily weld?

* What are some basic safety procedures?

* What types of equipment are needed?

* How do you select filler metal (welding rod)?

* How is the equipment set up?

* What are the joint preparations for welding?

* How are welds judged?

* Oxyacetylene welding tips from West Coast Customs

Chapter 4: Shielded Metal Arc Welding: Arc Welding and Stick Welding

* How does the process work?

* When can stick welding be used?

* What is the basic equipment setup for stick welding?

* What are the functions of stick welding electrodes and how are they

selected?

* How is stick welding equipment set up?

* Stick welding tips from West Coast Customs

Chapter 5: Wire Feed Welding Processes: MIG Welding and Fluxed Cored Arc

Welding

* How does the MIG process work?

* What metals can MIG weld?

* What is the basic equipment for MIG Welding?

* How do you select MIG electrodes?

* What part does shielding gas play in the MIG process?

* How is the welding wire transferred to the welding pool?

* How is MIG equipment set up?

* What are some joint preparation steps for MIG welding?

* How does the orientation of the electrode during welding affect the

weld?

* What are typical MIG welding problems and solutions?

* How does the flux cored arc welding process work?

* What equipment is needed for an FCAW welding outfit?

* How do you select FCAW electrodes?

* What are typical FCAW problems and solutions?

* How is FCAW equipment set up?

* MIG welding tips from West Coast Customs

Chapter 6: Gas Tungsten Arc Welding: TIG Welding

* How does the process work?

* What is the basic equipment setup for TIG welding?

* How are the electrodes selected?

* What shielding gases are used with TIG welding?

* What is the TIG welding setup process?

* What are some problems and solutions for TIG welding?

* TIG welding tips from West Coast Customs

Chapter 7: Thermal Cutting: Oxy-Fuel Cutting and Plasma Arc Cutting

* How does oxyacetylene cutting work?

* How does a cutting head differ from a welding torch?

* What other fuels can be used in oxy-fuel cutting?

* How do you set up cutting torch equipment?

* What are some basic cutting techniques?

* What are OFC troubleshooting techniques?

* What is plasma arc cutting?

* Plasma arc cutting tips from West Coast Customs

Chapter 8: Brazing and Soldering

* What’s the difference between brazing and soldering?

* What are the types of brazing/soldering?

* What are some common joint designs?

* What’s the purpose of brazing and soldering fluxes?

* What are the properties of brazing filler materials and soldering

alloys?

* What steps help ensure safe brazing and soldering?

* How do you solder copper tubing?

* What are some troubleshooting tips for soldered and brazed joints?

* Braze Welding tips from West Coast Customs

Chapter 9: Welding Tasks and Tips

* What’s the best corner treatment for a welded rectangular frame?

* What’s the best way to check if corners are square?

* How should a cracked C-channel truck frame be repaired?

* What are some tips for welding pipe and tubing?

* What are some ways to deal with metal distortion?

Glossary

Index

Chapter 1: An Overview of Welding

* What are the most popular welding processes for the

do-it-yourselfer?

* How are welding joints prepared?

* What are some of the basic types of welds?

* What are the special procedures for welding thick plates?

* What are some common welding positions?

Chapter 2: General Tools, Materials and Safety Equipment

* What hand tools are used in welding?

* What power tools are used in welding?

* What types of clamps are used in welding?

* What are the most common steel products used in welding?

* What are some basic safety requirements?

Chapter 3: Oxyacetylene Welding

* What are the applications that OAW is best suited for?

* What metals can the OAW process readily weld?

* What are some basic safety procedures?

* What types of equipment are needed?

* How do you select filler metal (welding rod)?

* How is the equipment set up?

* What are the joint preparations for welding?

* How are welds judged?

* Oxyacetylene welding tips from West Coast Customs

Chapter 4: Shielded Metal Arc Welding: Arc Welding and Stick Welding

* How does the process work?

* When can stick welding be used?

* What is the basic equipment setup for stick welding?

* What are the functions of stick welding electrodes and how are they

selected?

* How is stick welding equipment set up?

* Stick welding tips from West Coast Customs

Chapter 5: Wire Feed Welding Processes: MIG Welding and Fluxed Cored Arc

Welding

* How does the MIG process work?

* What metals can MIG weld?

* What is the basic equipment for MIG Welding?

* How do you select MIG electrodes?

* What part does shielding gas play in the MIG process?

* How is the welding wire transferred to the welding pool?

* How is MIG equipment set up?

* What are some joint preparation steps for MIG welding?

* How does the orientation of the electrode during welding affect the

weld?

* What are typical MIG welding problems and solutions?

* How does the flux cored arc welding process work?

* What equipment is needed for an FCAW welding outfit?

* How do you select FCAW electrodes?

* What are typical FCAW problems and solutions?

* How is FCAW equipment set up?

* MIG welding tips from West Coast Customs

Chapter 6: Gas Tungsten Arc Welding: TIG Welding

* How does the process work?

* What is the basic equipment setup for TIG welding?

* How are the electrodes selected?

* What shielding gases are used with TIG welding?

* What is the TIG welding setup process?

* What are some problems and solutions for TIG welding?

* TIG welding tips from West Coast Customs

Chapter 7: Thermal Cutting: Oxy-Fuel Cutting and Plasma Arc Cutting

* How does oxyacetylene cutting work?

* How does a cutting head differ from a welding torch?

* What other fuels can be used in oxy-fuel cutting?

* How do you set up cutting torch equipment?

* What are some basic cutting techniques?

* What are OFC troubleshooting techniques?

* What is plasma arc cutting?

* Plasma arc cutting tips from West Coast Customs

Chapter 8: Brazing and Soldering

* What’s the difference between brazing and soldering?

* What are the types of brazing/soldering?

* What are some common joint designs?

* What’s the purpose of brazing and soldering fluxes?

* What are the properties of brazing filler materials and soldering

alloys?

* What steps help ensure safe brazing and soldering?

* How do you solder copper tubing?

* What are some troubleshooting tips for soldered and brazed joints?

* Braze Welding tips from West Coast Customs

Chapter 9: Welding Tasks and Tips

* What’s the best corner treatment for a welded rectangular frame?

* What’s the best way to check if corners are square?

* How should a cracked C-channel truck frame be repaired?

* What are some tips for welding pipe and tubing?

* What are some ways to deal with metal distortion?

Glossary

Index

* What are the most popular welding processes for the

do-it-yourselfer?

* How are welding joints prepared?

* What are some of the basic types of welds?

* What are the special procedures for welding thick plates?

* What are some common welding positions?

Chapter 2: General Tools, Materials and Safety Equipment

* What hand tools are used in welding?

* What power tools are used in welding?

* What types of clamps are used in welding?

* What are the most common steel products used in welding?

* What are some basic safety requirements?

Chapter 3: Oxyacetylene Welding

* What are the applications that OAW is best suited for?

* What metals can the OAW process readily weld?

* What are some basic safety procedures?

* What types of equipment are needed?

* How do you select filler metal (welding rod)?

* How is the equipment set up?

* What are the joint preparations for welding?

* How are welds judged?

* Oxyacetylene welding tips from West Coast Customs

Chapter 4: Shielded Metal Arc Welding: Arc Welding and Stick Welding

* How does the process work?

* When can stick welding be used?

* What is the basic equipment setup for stick welding?

* What are the functions of stick welding electrodes and how are they

selected?

* How is stick welding equipment set up?

* Stick welding tips from West Coast Customs

Chapter 5: Wire Feed Welding Processes: MIG Welding and Fluxed Cored Arc

Welding

* How does the MIG process work?

* What metals can MIG weld?

* What is the basic equipment for MIG Welding?

* How do you select MIG electrodes?

* What part does shielding gas play in the MIG process?

* How is the welding wire transferred to the welding pool?

* How is MIG equipment set up?

* What are some joint preparation steps for MIG welding?

* How does the orientation of the electrode during welding affect the

weld?

* What are typical MIG welding problems and solutions?

* How does the flux cored arc welding process work?

* What equipment is needed for an FCAW welding outfit?

* How do you select FCAW electrodes?

* What are typical FCAW problems and solutions?

* How is FCAW equipment set up?

* MIG welding tips from West Coast Customs

Chapter 6: Gas Tungsten Arc Welding: TIG Welding

* How does the process work?

* What is the basic equipment setup for TIG welding?

* How are the electrodes selected?

* What shielding gases are used with TIG welding?

* What is the TIG welding setup process?

* What are some problems and solutions for TIG welding?

* TIG welding tips from West Coast Customs

Chapter 7: Thermal Cutting: Oxy-Fuel Cutting and Plasma Arc Cutting

* How does oxyacetylene cutting work?

* How does a cutting head differ from a welding torch?

* What other fuels can be used in oxy-fuel cutting?

* How do you set up cutting torch equipment?

* What are some basic cutting techniques?

* What are OFC troubleshooting techniques?

* What is plasma arc cutting?

* Plasma arc cutting tips from West Coast Customs

Chapter 8: Brazing and Soldering

* What’s the difference between brazing and soldering?

* What are the types of brazing/soldering?

* What are some common joint designs?

* What’s the purpose of brazing and soldering fluxes?

* What are the properties of brazing filler materials and soldering

alloys?

* What steps help ensure safe brazing and soldering?

* How do you solder copper tubing?

* What are some troubleshooting tips for soldered and brazed joints?

* Braze Welding tips from West Coast Customs

Chapter 9: Welding Tasks and Tips

* What’s the best corner treatment for a welded rectangular frame?

* What’s the best way to check if corners are square?

* How should a cracked C-channel truck frame be repaired?

* What are some tips for welding pipe and tubing?

* What are some ways to deal with metal distortion?

Glossary

Index